BOX TYPE FURNACE SUPER MAX

This is a conventional front-loading type furnace. There is a wide range of heating elements from Kanthal wire, SiC, molybdenum disilicide, molybdenum to graphite heaters according to specific use. We design the furnace temperature up to 2500 combining the heating element and insulation structure. We also modify the system to be a vacuum oven using plate heaters, a vacuum de-waxing furnace using a tight box, and more.

SUPER MAX

HIGH PERFORMANCE FRONT-DOOR HIGH TEMPERATURE FURNACES

High speed ramp-up furnaces, meeting various needs such as research and development of fine ceramics, new glass, new materials, and product evaluation and management, and small production and so on.

Due to sliding front door, work can be taken out safely at high temperature.

SPX1518T-17

※Support table is optional.

| MODEL | SPX1518T-17 | SPX2025-17 | SPX2035-17 |

|---|---|---|---|

| TYPE | FRONT DOOR SQUARE | ||

| TEMPERATURE | OPERATING MAX 1700℃ | ||

| HOT ZONE | W150×H160×D180 | W200×H200×D250 | W200×H200×D350 |

| HEATER | MOLYBDENUM DISILICIDE | ||

| INSULATION | CERAMIC FIBER INSULATION | ||

| OUTPUT | 3KW | 6.5KW | 9.7KW |

| CONTROL | ZONE PID PROGRAM CONTROL | ||

| OVERHEAT ALARM | CONTROLLER ALARM SET | ||

| CONTROL PANEL | SIDE OF FURNACE | BASE OF FURNACE | |

| ELECTRICITY | SINGLE PHASE 200V 5KVA | SINGLE PHASE 200V 8KVA |

SINGLE PHASE 200V 11KVA |

| ※OPTIONS | RECORDER, INSIDE MONITOR T/C, FLOW METER, SUPPORT TABLE (For SPX1518T) |

| MODEL | SPX1518T-17 |

|---|---|

| TYPE | FRONT DOOR SQUARE |

| TEMPERATURE | OPERATING MAX 1700℃ |

| HOT ZONE | W150×H160×D180 |

| HEATER | MOLYBDENUM DISILICIDE |

| INSULATION | CERAMIC FIBER INSULATION |

| OUTPUT | 3KW |

| CONTROL | ZONE PID PROGRAM CONTROL |

| OVERHEAT ALARM | CONTROLLER ALARM SET |

| CONTROL PANEL | SIDE OF FURNACE |

| ELECTRICITY | SINGLE PHASE 200V 5KVA |

| MODEL | SPX2025-17 |

|---|---|

| TYPE | FRONT DOOR SQUARE |

| TEMPERATURE | OPERATING MAX 1700℃ |

| HOT ZONE | W200×H200×D250 |

| HEATER | MOLYBDENUM DISILICIDE |

| INSULATION | CERAMIC FIBER INSULATION |

| OUTPUT | 6.5KW |

| CONTROL | ZONE PID PROGRAM CONTROL |

| OVERHEAT ALARM | CONTROLLER ALARM SET |

| CONTROL PANEL | BASE OF FURNACE |

| ELECTRICITY | SINGLE PHASE 200V 8KVA |

| MODEL | SPX2035–17 |

|---|---|

| TYPE | FRONT DOOR SQUARE |

| TEMPERATURE | OPERATING MAX 1700℃ |

| HOT ZONE | W200×H200×D350 |

| HEATER | MOLYBDENUM DISILICIDE |

| INSULATION | CERAMIC FIBER INSULATION |

| OUTPUT | 9.7KW |

| CONTROL | ZONE PID PROGRAM CONTROL |

| OVERHEAT ALARM | CONTROLLER ALARM SET |

| CONTROL PANEL | SIDE OF FURNACE |

| ELECTRICITY | SINGLE PHASE 200V 11KVA |

※OPTIONS

RECORDER, INSIDE MONITOR T/C, FLOW METER,

SUPPORT TABLE (For SPX1518T)

※Specifications are subject to change without notice.

Hot zone dimensions other than those listed above are also available.

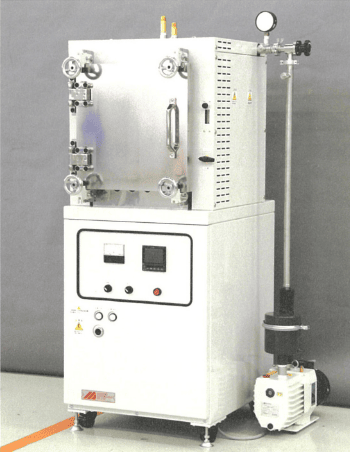

SUPER MAX(Ⅴ)

HIGH PERFORMANCE

VACUUM REPLACED

MULTI ATMOSPHERE

TUBE FURNACE

Multi-atmosphere sintering such as air, O2, N2, Ar and so on by vacuum replacement.

SPX2025-17V

*Recorder and vacuum pump are optional.

| MODEL | SPX1518-17V | SPX2025-17V |

|---|---|---|

| TYPE | FRONT DOOR SQUARE | |

| TEMPERATURE | OPERATING MAX 1700℃ | |

| ATMOSPHERES | AIR, O2, Ar, He, N2 | |

| HOT ZONE | W150×H160×D180 | W200×H200×D250 |

| HEATER | MOLYBDENUM DISILICIDE | |

| INSULATION | CERAMIC FIBER INSULATION | |

| OUTPUT | 3KW | 6.5KW |

| CONTROL | ZONE PID PROGRAM CONTROL | |

| OVERHEAT ALARM | CONTROLLER ALARM SET | |

| VACUUM GAUGE | CONPOUND GAUGE | |

| ELECTRICITY | SINGLE PHASE 200V 5KVA | SINGLE PHASE 200V 8KVA |

| COOLING WATER | 5ℓ/min 25A | |

| ※OPTIONS | RECORDER, INSIDE MONITOR T/C, PIRANI VACUUM GAUGE, VACUUM PUMP, MASS FLOW CONTROLLER |

| MODEL | SPX1518-17V |

|---|---|

| TYPE | FRONT DOOR SQUARE |

| TEMPERATURE | OPERATING MAX 1700℃ < |

| ATMOSPHERES | Air, O2, Ar, He, N2 |

| HOT ZONE | W150×H160×D180 |

| HEATER | MOLYBDENUM DISILICIDE |

| INSULATION | CERAMIC FIBER INSULATION |

| OUTPUT | 3KW |

| CONTROL | ZONE PID PROGRAM CONTROL |

| OVERHEAT ALARM | CONTROLLER ALARM SET |

| VACUUM GAUGE | CONPOUND GAUGE |

| FLOW METER | 1 FOR N2 5ℓ/min |

| ELECTRICITY | SINGLE PHASE 200V 5KVA |

| COOLING WATER | 5ℓ/min 25A |

| MODEL | SPX2025-17(V) |

|---|---|

| TYPE | FRONT DOOR SQUARE |

| TEMPERATURE | OPERATING MAX 1700℃ |

| ATMOSPHERES | Air, O2, Ar, He, N2 |

| HOT ZONE | W200×H200×D250 |

| HEATER | MOLYBDENUM DISILICIDE |

| INSULATION | CERAMIC FIBER INSULATION |

| OUTPUT | 6.5KW |

| CONTROL | ZONE PID PROGRAM CONTROL |

| OVERHEAT ALARM | CONTROLLER ALARM SET |

| VACUUM GAUGE | CONPOUND GAUGE |

| FLOW METER | 1 FOR N2 5ℓ/min |

| ELECTRICITY | SINGLE PHASE 200V 8KVA |

| COOLING WATER | 5ℓ/min 25A |

※OPTIONS

RECORDER, INSIDE MONITOR T/C, FLOW METER,

SUPPORT TABLE (For SPX1518T)

※Specifications are subject to change without notice.

Hot zone dimensions other than those listed above are also available.