SPECIALIZED FURNACES

MARUSHO DENKI’s heating technology is highly regarded by customers in various fields from food processing, printing and film curing, wire annealing and CVD, superconductor processing, optical glass melting, pressing and annealing, preforming synthesized quartz, single crystal growing, highly purifing titanium to heating gases. We design and manufacture furnaces from laboratory use to production scale under the know-how and technologies of designing heaters and insulation, vaccum and gas control, dew point and PO2 control and more.

SMALL HIGH TEMPERATURE

FURNACE FOR PULLING TEST

Specifications

- ●Max.1500℃

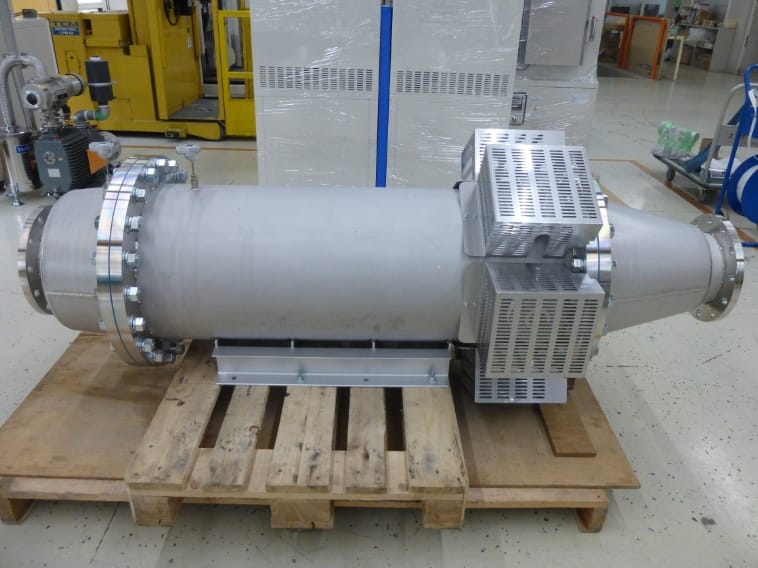

HIGH TEMPERATURE

HOT AIR HEATER

Specifications

- ●Max.1000℃

- ●Atmosphere: Nitrogen, Oxygen, Argon, Air

Operating temperature to be discussed

SWING FURNACE

TEST FURNACE

FOR HEAT & COOL CYCLE

Specifications

- ●Dimension:φ200×H220

- ●Operating: 1600°C

- ●Equipped with shutter at the bottom of furnace body and forced cooling blower

- ●1750℃~1800℃, to be discussed

CARBON NANOTUBE

R&D FURNACE

HIGH TEMPERATURE

FURNACE

WITH OBSERVATION

WINDOWS

VACUUM & ATMOSPHERE

QUENCH FURNACE

Specifications

- ●Max.1600℃

- ●Atmosphere:Nitrogen, Oxygen, Argon,

Air, Vacuum

Operating temperature to be discussed

REVOLVING FURNACE

FOR POWDER

Specifications

- ●Max.1000℃

HOT PLATE VACUUM

FURNACE

Specifications

- ●Max.350℃

CART-DRAW TYPE LARGE SCALE

ATMOSPHERE SINTERING

FURNACE

Specifications

- ●Max.1650℃

- ●24-zone control

- ●Exhaust gas processing furnace

- ●Programmable cooling system

- ●Atmosphere: Nitrogen, Oxygen, Argon, Air

Operating temperature to be discussed