BIG MAN

BIG MAN is a bottom-up type furnace for manufacturing which makes full use of all MARUSHO DENKI’s expertise and technology to ensure high standards of productivity, reliability and performance, the three essentials for use in mass production, as well as in small-volume production of wide range of items. Heaters located on all sides and automatic bottom-up system make a larger temperature uniform zone and better cost performance than convetional units. With the programmable cooling system, the hearth traversing system and the automatic hearth exchange system, BIG MAN provides a perfect line of production furnaces.

There are also other models of BIG MAN such as gas-flow replaced type (gas-tight type), vacuum replaced type, vacuum replaced positive pressure type, vacuum replaced circulation type,high vacuum furnace , vacuum furnace with inner muffle etc. Each model can be equipped with atmosphere circulaton type programmable cooling system and automatic hearth exchange system to provide better cost performance and higher productivity. According to the combination of heaters and insulation, atomosphere such as air, nitrogen, hydrogen, oxygen, argon, or helium can be attained. There are a wide range of heaters such as molybdenum disilicide, molybdenum, tungsten, sic, kanthal, ni-cr, graphite, sheeth heaters.

We, of course, modify the standard models as well as design and manufacture furnaces according to your specifications.

BIGMAN

(BOTTOM-UP TYPE)

STANDARD TYPE

- ●Operating:1600℃(Air)

- ●Max:1700℃

- ●Programmable cooling system(optional)

AUTOMATIC HEARTH

EXCHANGE TYPE

- ●Dimension:W600 × D600 × H600

- ●Operating:700°C (AIR)

- ●Max:B00°C

- ●Hearth: Electrically moving up-and-down and traversing exchange type

- ●Three-zone control

- ●Programmable cooling system (optional)

- ●Capable of being modified operating temperatures up

CERAMIC DEWAXING &

SINTERING FURNACE

- ●Operating:1600°C

- ●Max:1700°C

- ●Three-zone control

- ●Exhaust gas processing furnace

- ●Programmable cooling system

DEWAXING AND SINTERING

FURNACE FOR FERRITE

- ●Dimension:W830 × D830 × H880

- ●Operating:1350°C

- ●Max:1400°C

- ●Gas flow rate: Mass flow setting automatic switching control

- ●Programmable oxygen concentration control

- ●Atmosphere circulation with programmable

cooling system

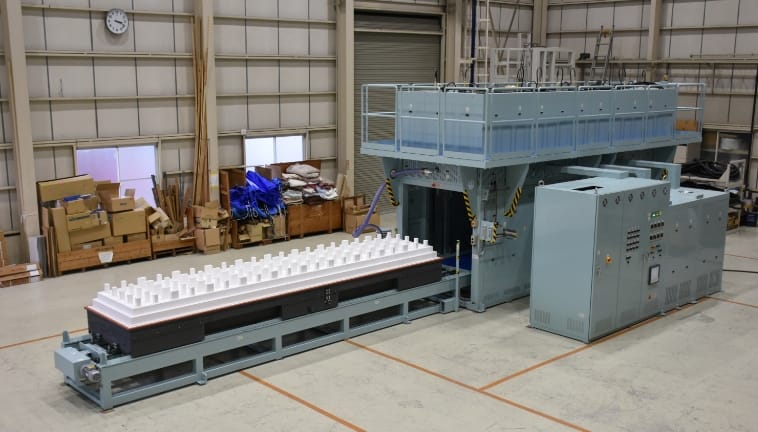

ULTRA LARGE SCALE

ATMOSPHERE

SINTERING FURNAVE

- ●Operating: 1600°C (Air, Oxygen)

- ●Max:1650℃ (Air, Oxygen)

- ●Hearth: Electrically moving up-and-down and traversing type

- ●8-zone control

- ●Programmable cooling system

VACUUM BRAZING FURNACE

- ●Dimension:W600 × D600 × H750

- ●Operating:700℃ (Vacuum)

- ●Max:750℃

- ●Vertical 3-zone control

- ●Automatic exchange of two hearths

- ●Equipped with oil diffusion pump

VACUUM REPLACED

PRESSURIZED

ATMOSPHERE SINTERING

FURNACE

- ●Operating:1600℃ (Air, Oxygen)

- ●Max: 1700℃ (Air, Oxygen)

- ●Vacuum replacement pressurized oxygen specification (0.1kgf/㎠ or less)

- ●Programmable pressure control

- ●10-zone control

- ●Programmable cooling system

- ●Atmosphere: Nitrogen, Oxygen, Argon, Air

Operating temperatures to be discussed